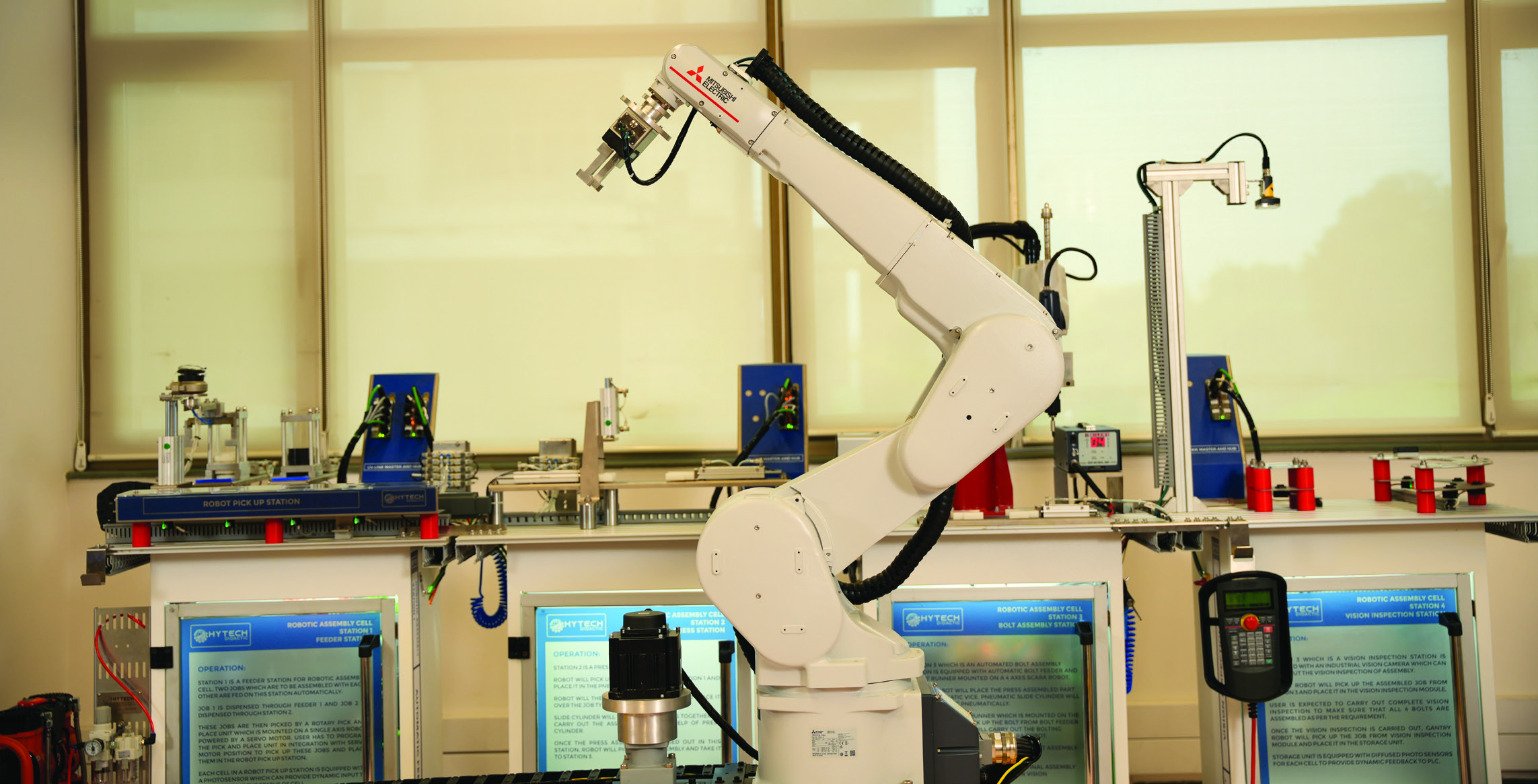

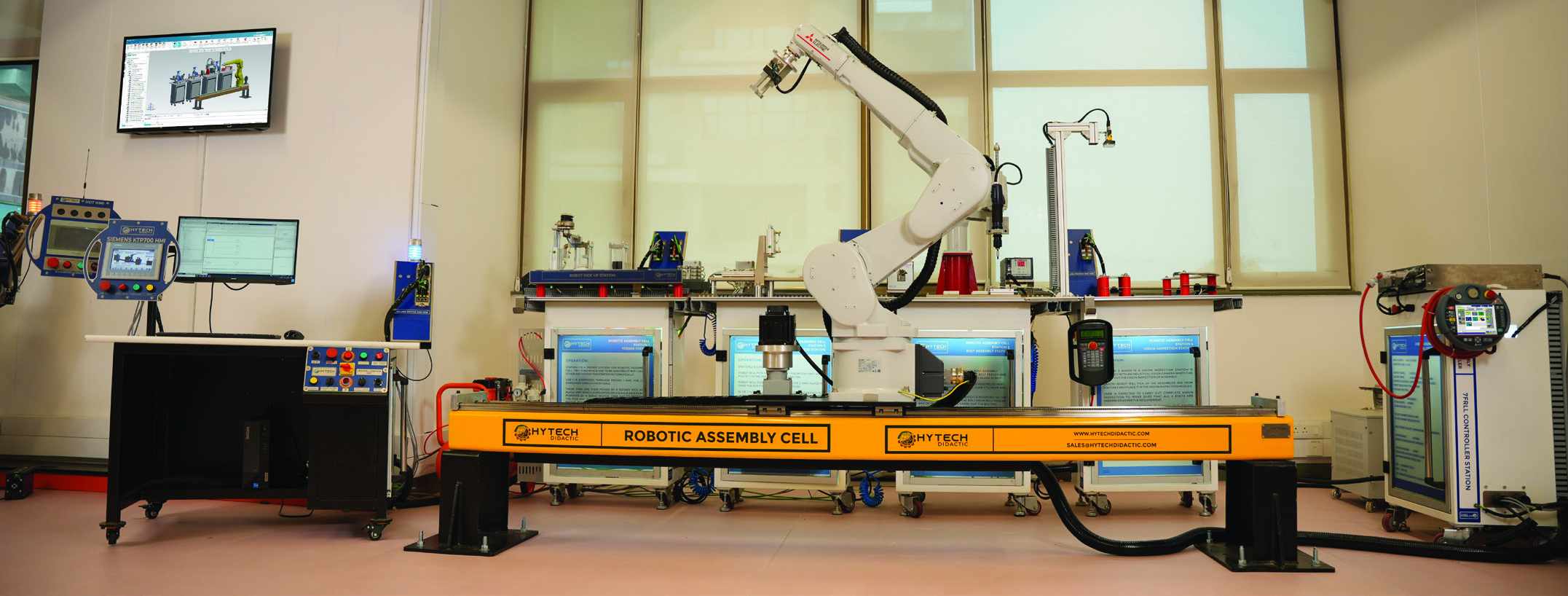

Integrated Robotic Assembly Cell With Dual Robots

Hytech Didactic integrated assembly cell is an integrated robotic cell which provides users with hands on experience on robotic bolt assembly process. This cell is integrated with PLC – HMI and SCADA. Four automation stations are provided to carry out assembly process along with vision inspection. This cell includes an industrial 7 axes robot with industrial linear gantry axis and a four axes SCARA Robot with a DC Nut runner attachment.

This Robotic cell provides exposure on not only robotics but also on mechatronics based applications including PLC HMI and SCADA. User is expected to integrate various automation processes with robots through SCADA.

User can design new screen on SCADA Runtime and design new algorithms as well as processes on the PLC and SCADA.

The process in this setup includes automatic dispensing of two different jobs, press assembly of dispensed jobs, bolt assembly of assembled jobs and vision inspection end product.

User is exposed to various industrial processes such as bolt assembly by a DC Nut runner mounted on a SCARA Robot and integration of 7 Axes industrial robot with entire system through PLC and SCADA.

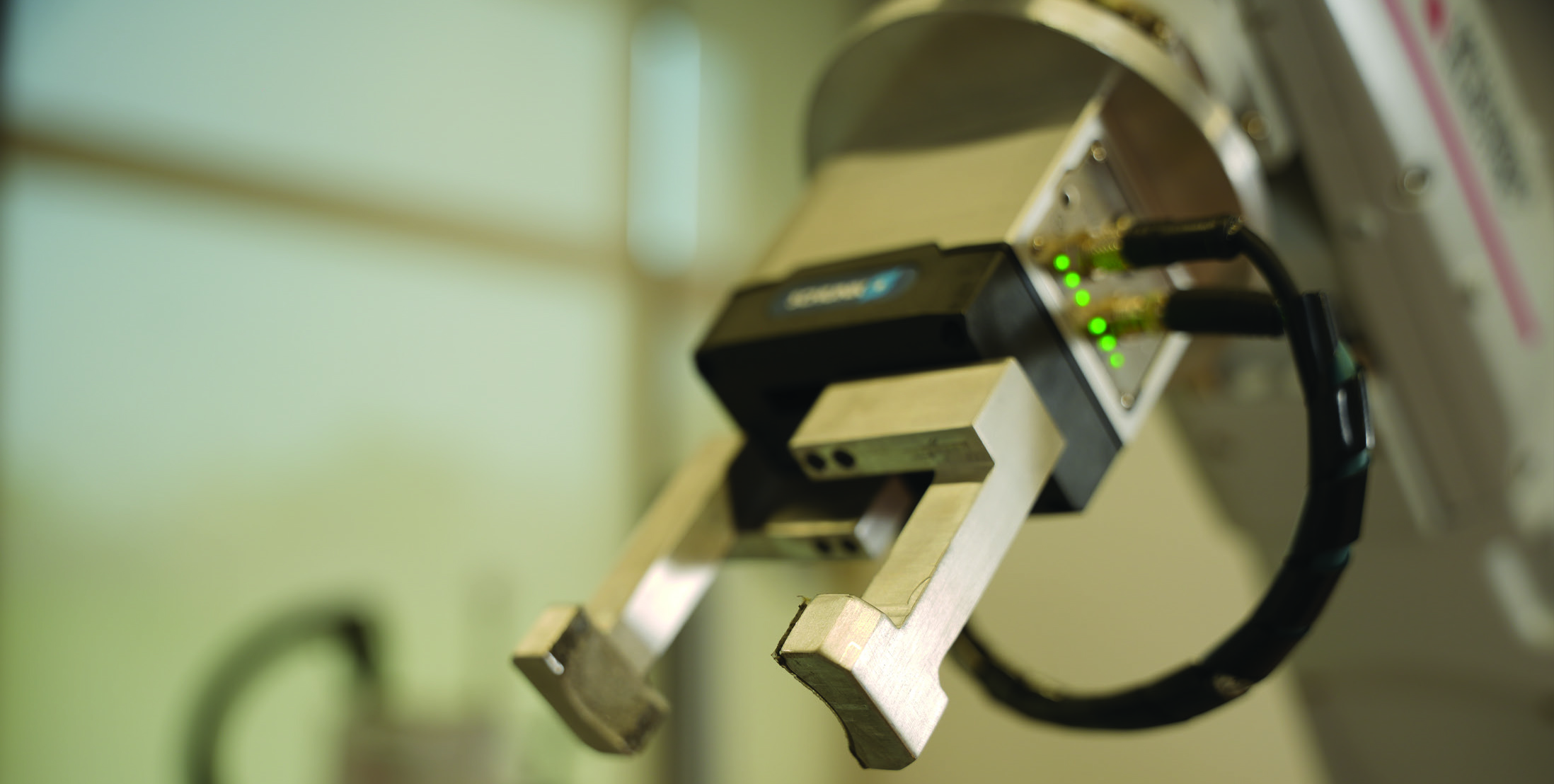

End Effectors of the robots include a DC Nut runner with torque control and profinet based universal gripper which can be utilized for jobs of various sizes. User is exposed to industrial DC Nut runner with torque control in integration with a SCARA Robot for automated bolt assembly application.

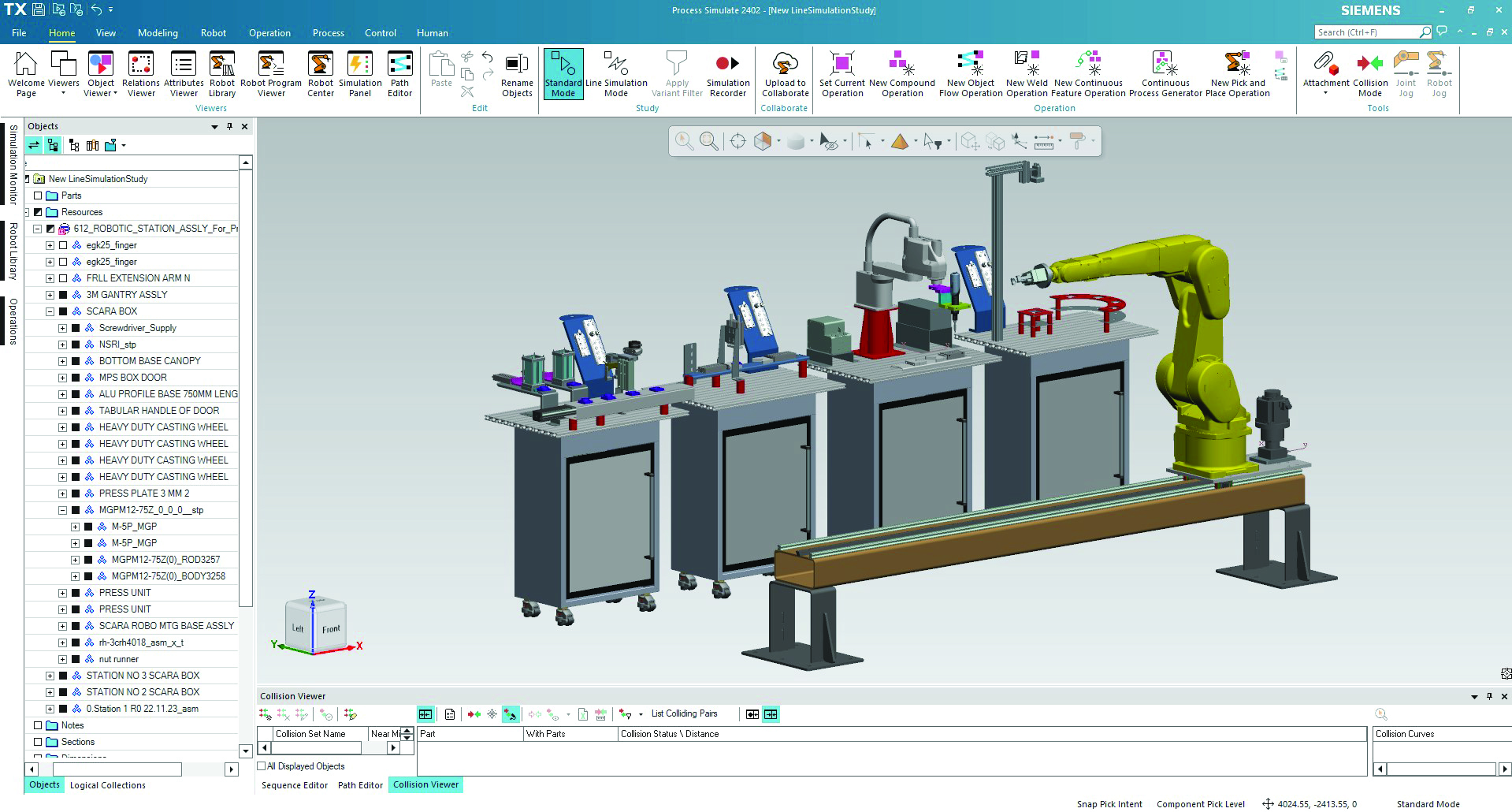

With this state of the art robotic cell, users are exposed to latest integrated robotic programming by integrating two robots, PLC, HMI and SCADA. Users can also utilize various offline programming software such as Siemens Technomatix to carry out complex robotic programming and avoid collision.

| Process | |

|---|---|

| Step 1 | Process starts on Station 1 which is controlled from the CCU (Central Control Unit) with S7 1500 PLC and SCADA. Communication with a CCU is through i/o link connectivity (Profinet). Raw Job 1 is fed with a pneumatically actuated auto feeder. Raw Job 2 is also fed with a separate pneumatically actuated auto feeder. |

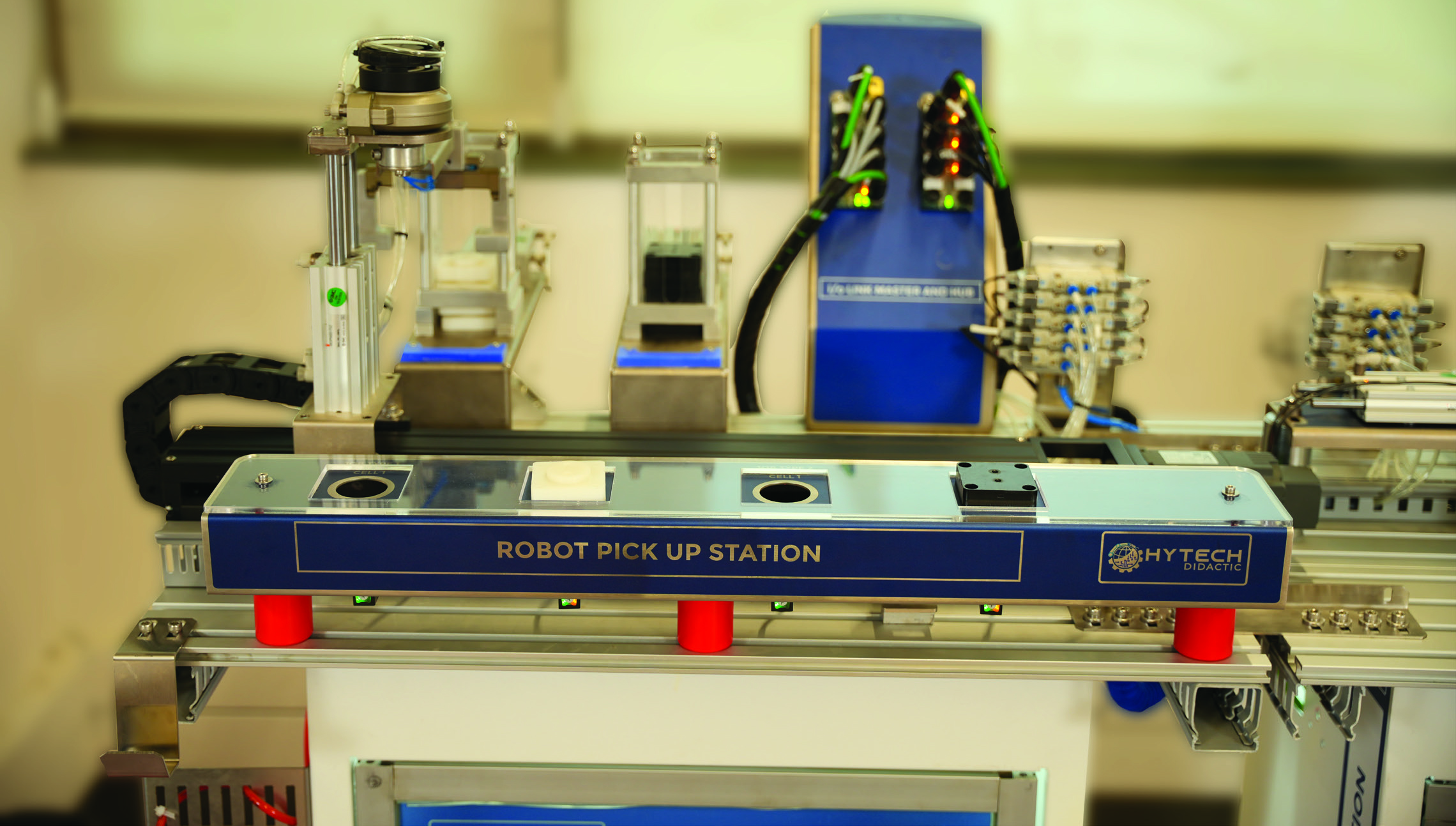

| Step 2 | Pneumatic pick and place unit mounted on a Servo Slide picks up a Raw Job 1 and 2 and places them on Robot pick up Pallet. Each cell on Robot pick up pallet is equipped with a diffused photosensor. |

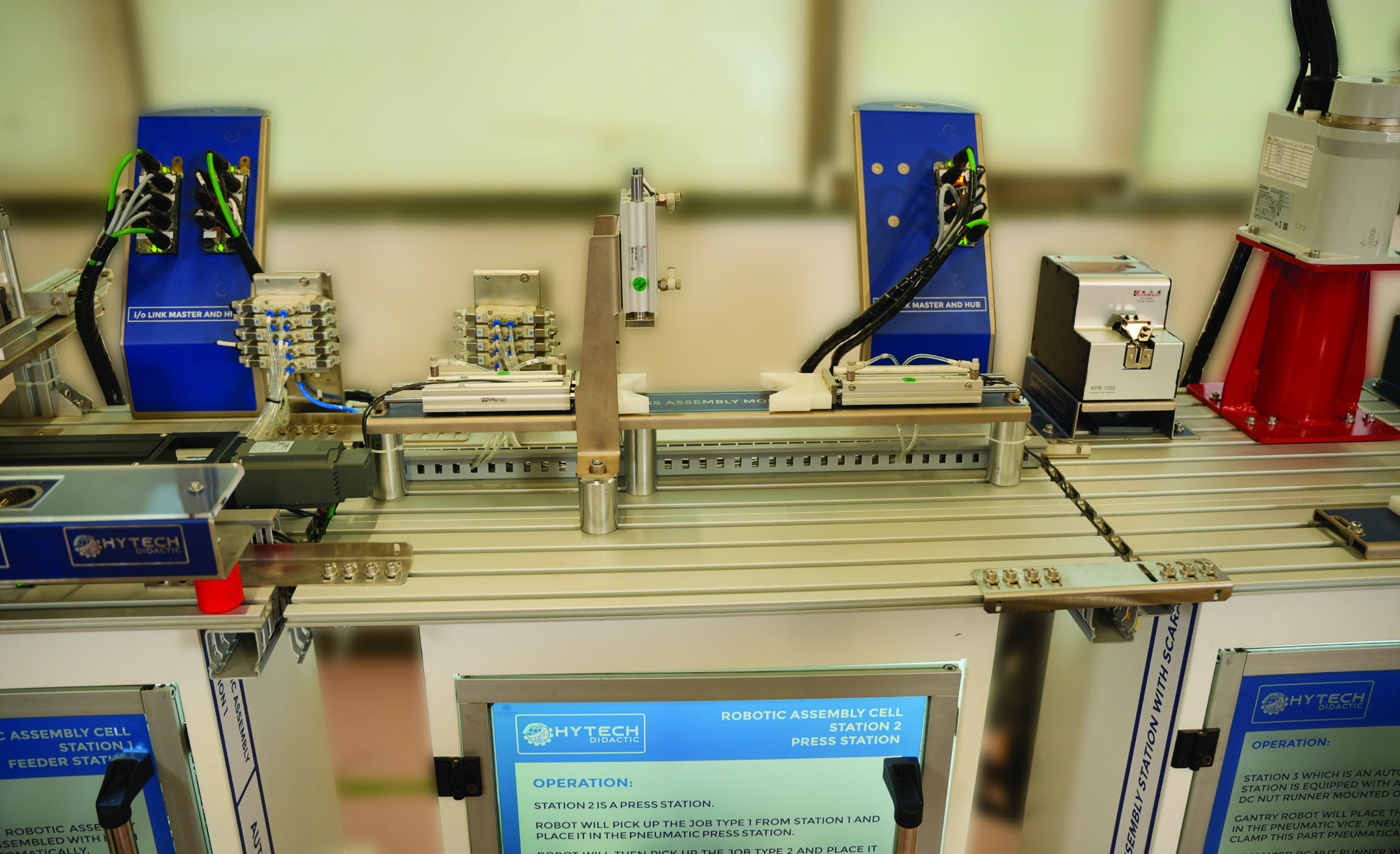

| Step 3 | Robot 1 picks up Job type 1 and Job type 2 from Robot Pick up pallet and places them in station 2. In station 2, both jobs are assembled together with a pneumatic press module. Station 2 is also controlled directly from CCU through SCADA. Robot then picks up the assembly and places it in Station 3. |

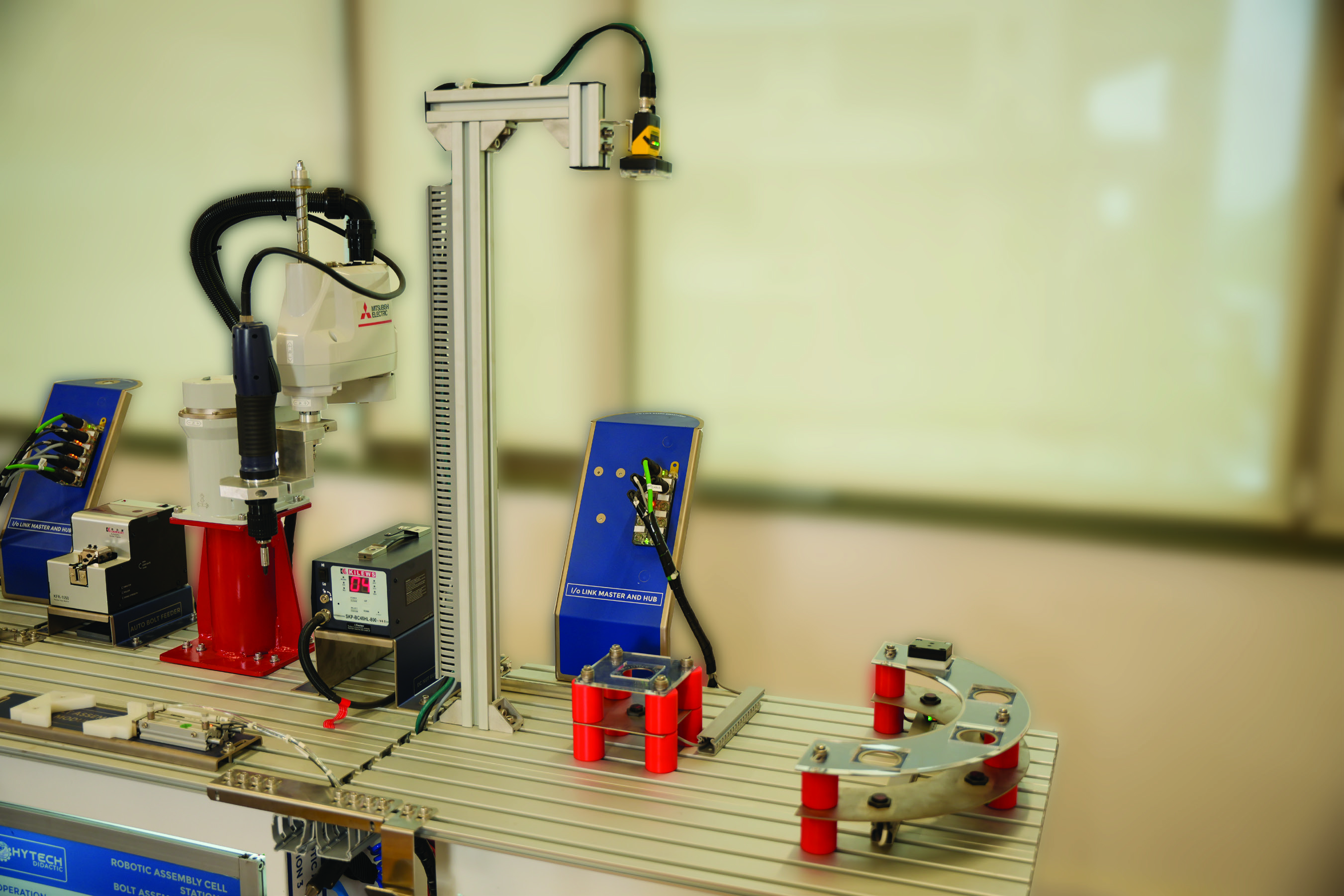

| Step 4 | In station 3, SCARA Robot carries out the bolt assembly of two jobs with the help of DC Nut Runner. Once the assembly is complete, Robot 1 picks up the assembled job and places it in station 4. |

| Step 5 | In station 4, Vision inspection of the job is carried out with vision system and final jobs are stored in the final storage unit. Each cell in the storage unit is equipped with a diffused photosensor for dynamic feedback. |

| List of Experiments | |

|---|---|

| 1 | PLC Based Operation of Station 1 with Servo Slide and Pneumatic pick and place unit integration. |

| 2 | SCADA Based operation of Station 1 with runtime operation |

| 3 | Operation of Station 1 and 2 with Robot 1 (7 Axes Robot) integration through SCADA |

| 4 | Bolt Assembly Process on Station 3 in integration with SCARA, DC Nut Runner , Bolt Feeder and SCADA |

| 5 | Vision Inspection on Station 4 through SCADA integration |

| 6 | Robot Programming (Articulated and SCARA) |

| 7 | Complete integrated bolt assembly Operation |

Station 1

Pneumatic Auto Feeders (Qty: 02)

Pneumatic Solenoid Valve Bank with i/o link / profinet connectivity

Servo Slide with minimum travel of 500mm

Pneumatic pick and place assembly with rotary motor and parallel gripper

Robot pick up pallet with diffused photosensors (Minimum qty: 04)

Station 2

Pneumatic Press Assembly Station with Slide Cylinders

Pneumatic Solenoid Valve Bank with i/o link / profinet connectivity

Robot Gantry

Robot 1 is mounted on the gantry system which is an industrial gantry with rack pinion and linear motion guideway attachment. Robot is coupled with the gantry through planetary gearbox. Minimum travel of gantry axis is 2,500mm.

Station 3:

Bolt Assembly station with slide cylinder

4 Axes SCARA Robot with minimum reach of 400mm and payload capacity of 3 KG

PLC Controlled DC Nut Runner mounted on SCARA Robot

Auto Bolt Feeder system

Station 4:

Vision System from Cognex / Equivalent

Storage system with diffused photosensors (Minm Qty: 04)

Central Control Unit

Central Control Unit (CCU) is a central control station equipped with Siemens S7 1500 PLC and workstation for cell operation. CCU Workstation is equipped with SCADA as well as digital twin software for offline programming. Dual monitors provide user with ease as well as convenience in PLC as well as SCADA and Robot programming.

Software in CCU

With this state of the art robotic cell, users are exposed to latest integrated robotic programming by integrating two robots, PLC, HMI and SCADA. Users can also utilize various offline programming software such as Siemens Technomatix to carry out complex robotic programming and avoid collision.

| 1 | Siemens SCADA – Developer (WinCC Advance) – Perpetual Software |

| 2 | Mitsubishi RT Tool box / Fanuc Roboguide – Perpetual |

| 3 | Siemens Technomatix – Perpetual with dynamic integration for process simulation |

| 4 | SCADA Runtime for user operations |

Robot 1

Robot 1 is a 7 Axes Robot with 7th axis being the linear gantry axis controlled directly from the Robot teach pendant. Robot 1 is equipped with profinet controlled pneumatic gripper; stroke of which can be remotely controlled to hold different types of jobs.

| Make | Mitsubishi / Fanuc |

| Model | 7 FRLL (Mitsubishi) / M10iA-7L (Fanuc) Robot will be provided with 7th Axis arrangement controlled directly from Robot controller |

| Payload | Minimum 7 KG |

| Robot Reach | Minimum 1500mm |

| End Effector | Profinet controlled Universal gripper from Schunk. Users can control the torque as well as stroke of gripper. |

Robot 2

Robot 2 is a 4 Axes SCARA Robot with minimum reach of 400mm and minimum payload capacity of 3 KG. DC Nut Runner which is PLC controlled through CCU with minimum torque capacity of 6 Nm is mounted on the SCARA Robot.

| Make | Mitsubishi |

| Model | 3 CRH |

| Payload | Minimum 3KG |

| Robot Reach | Minimum 400mm |

| End Effector | Vacuum based gripper |