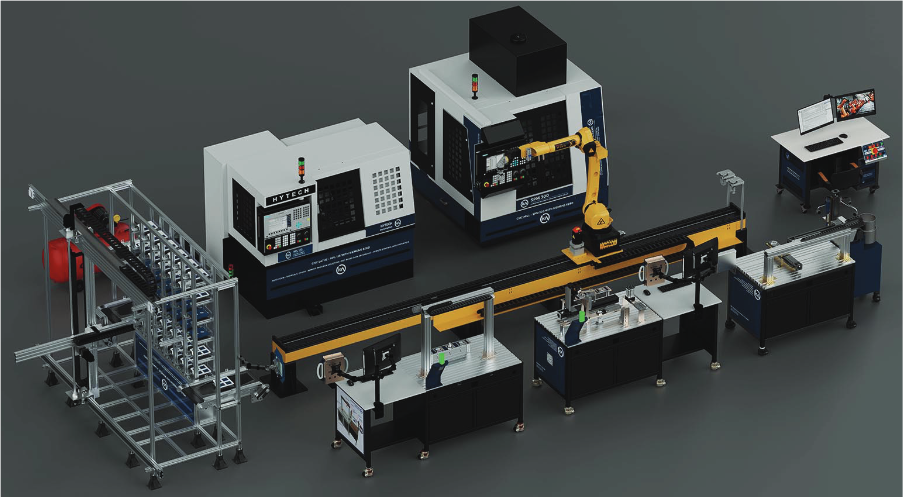

Computer Integrated Manufacturing System

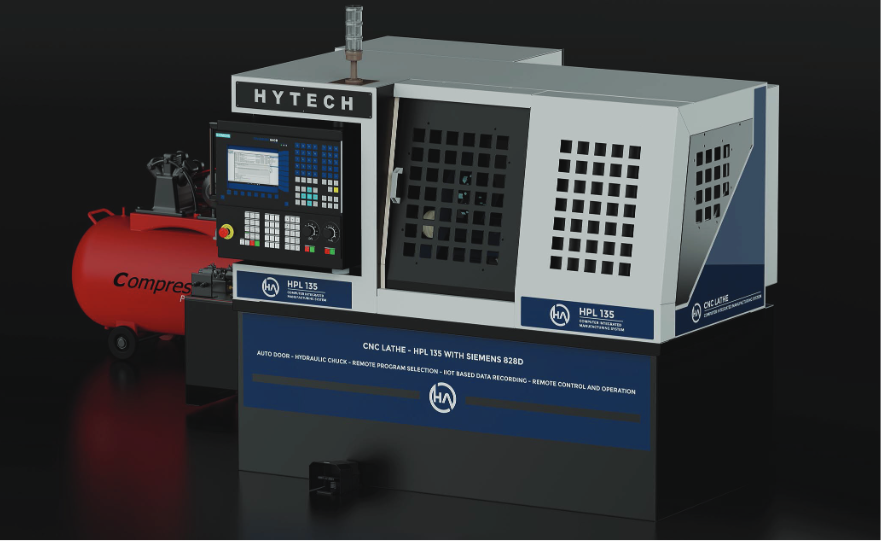

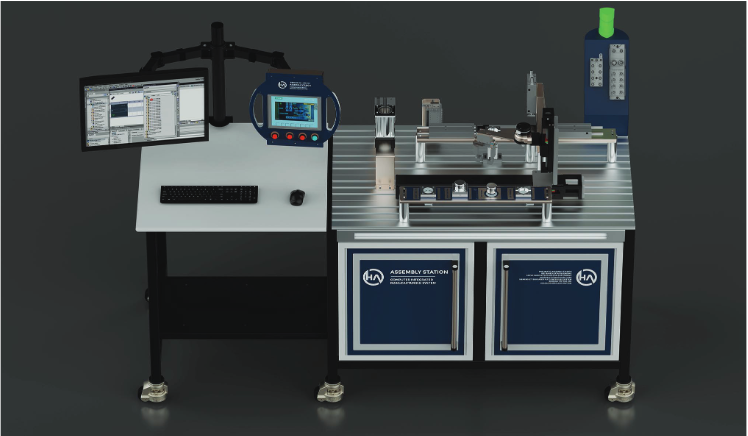

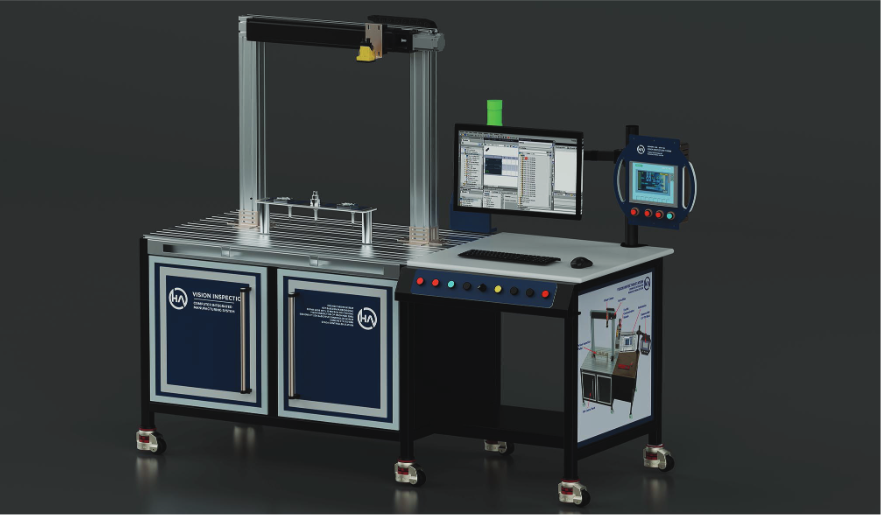

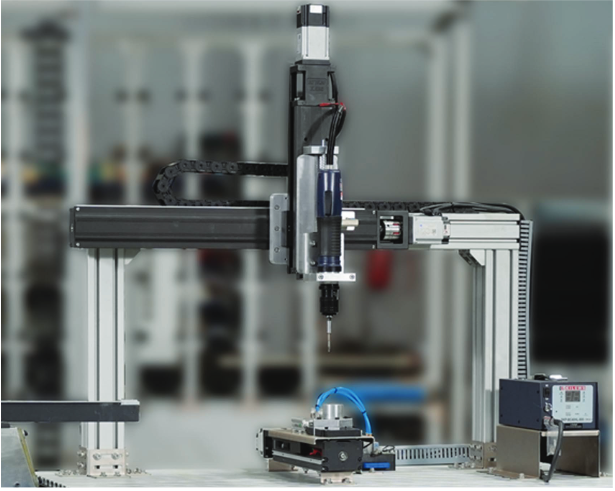

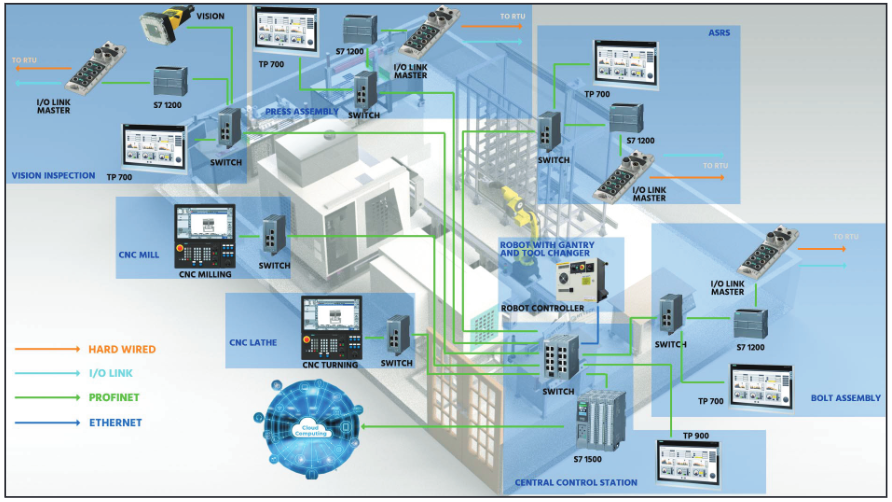

Computer Integrated manufacturing System from Hytech Automation is a completely integrated industrial automation based system with actual manufacturing processes such as turning and milling. CIM system consists of various industrial automation stations which are integrated with industrial SCADA system and a central PLC. Entire system is coupled with industrial MES as well as industrial digital twin software. User can operate each station / equipment in the entire system in individual mode as well as in integrated mode.

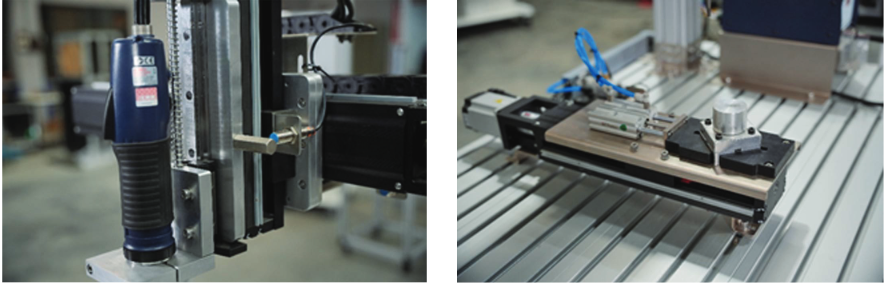

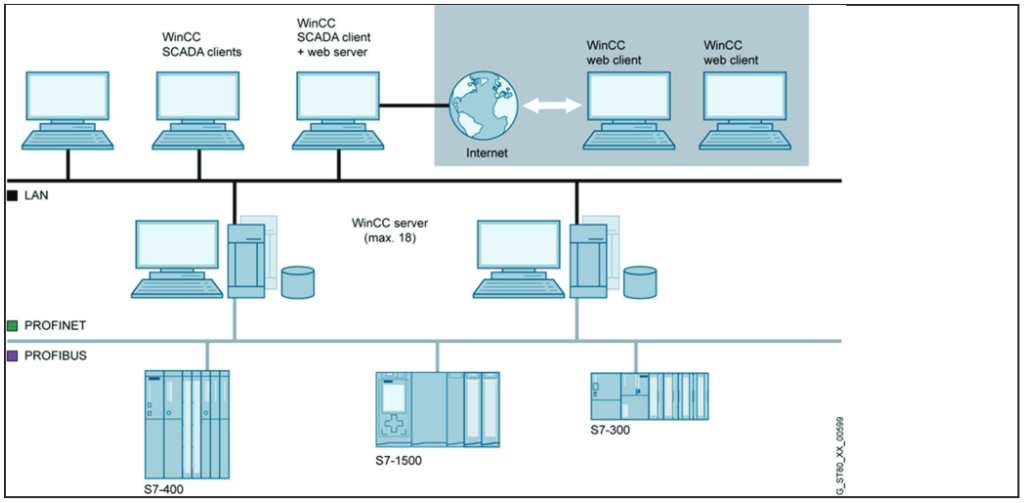

CIM System consists of actual machining processes such as CNC Turning and CNC Milling. Each station except the robot module and CNC Machines of the system is equipped with Siemens S7 1200 PLC and Siemens KTP 700 HMI. This allows user to program each station in individual mode and integrate it with the central control system through Siemens SCADA. Complete system is integrated with IIOT. This allows users to commission as well as operate the system remotely. Users can also collect various data points for AI and ML integrations.

Hytech Automation CIM System is also provided with complete fencing arrangement along with door latching switches as well as laser based security sensors providing complete industrial experience to users. Industrial components such as smart vision system, magnetic scales with analog feedback, i/o link communication with i/o link sensors are also provided with CIM system. Integration of this system with Augmented reality to create various process simulations provides users with additional skillset. With Process simulation software, users can create various case studies and simulate them as per industrial standards.

Various Machines / Stations in Computer Integrated Manufac- turing System:

- CNC Turning Machine

- CNC Milling Machine

- Automated Storage and Retrieval System

- Industrial Articulated Robot with Gantry Axis and Robot Tool Changer

- Pneumatic Press Assembly Station with PLC and HMI

- Vision Inspection Station with PLC and HMI

- Automatic Bolt Assembly Station with Automatic bolt feeder and DC Nut Runner

- Central Control Station with Siemens S7 1500 PLC and Siemens KTP 900 HMI (Integrated System)

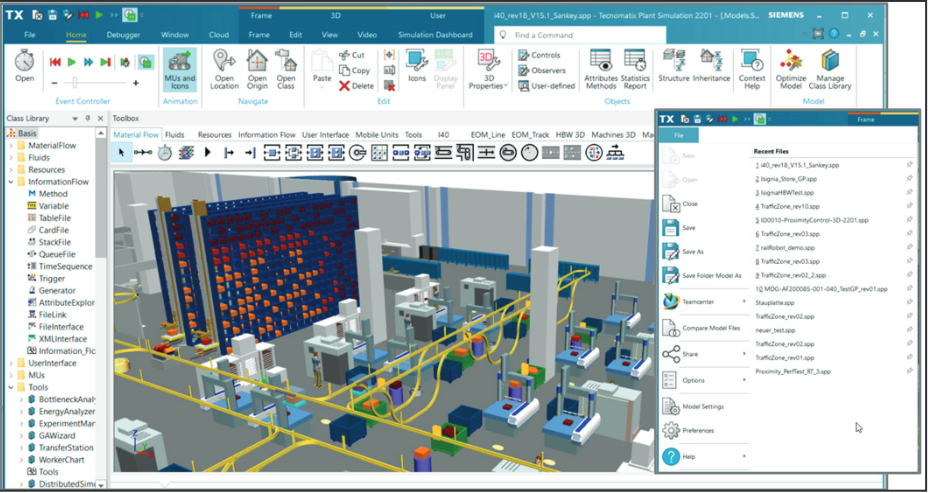

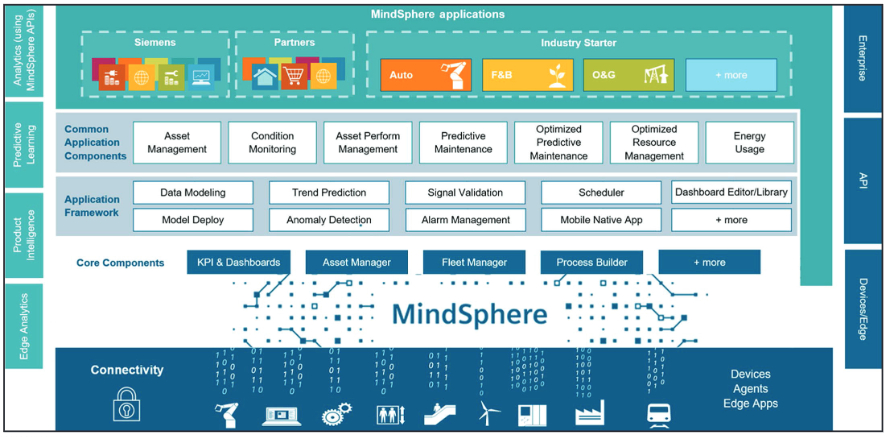

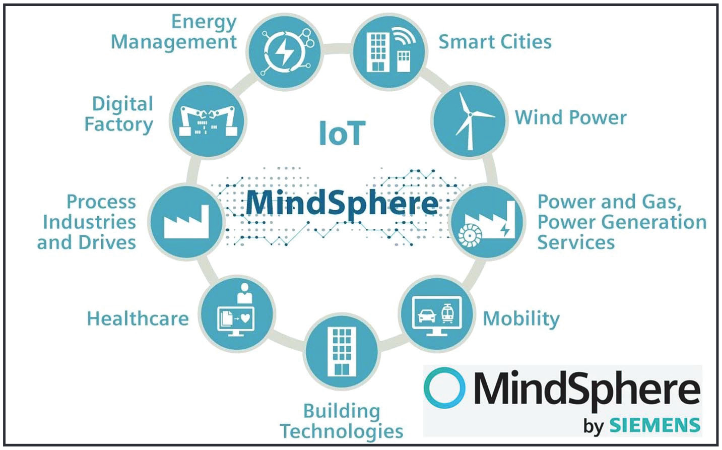

Various Software Integrated with Computer Integrated Manufacturing System:

- Siemens SCADA

- Siemens MES

- Digital Twin – Siemens Tech- nomatix

- Unity – Augmented Reality

- Remote Commissioning Software (PLC Based Digital Twin) – Siemens Mechatron- ics Concept Designe

- Siemens TIA for PLC and HMI programming

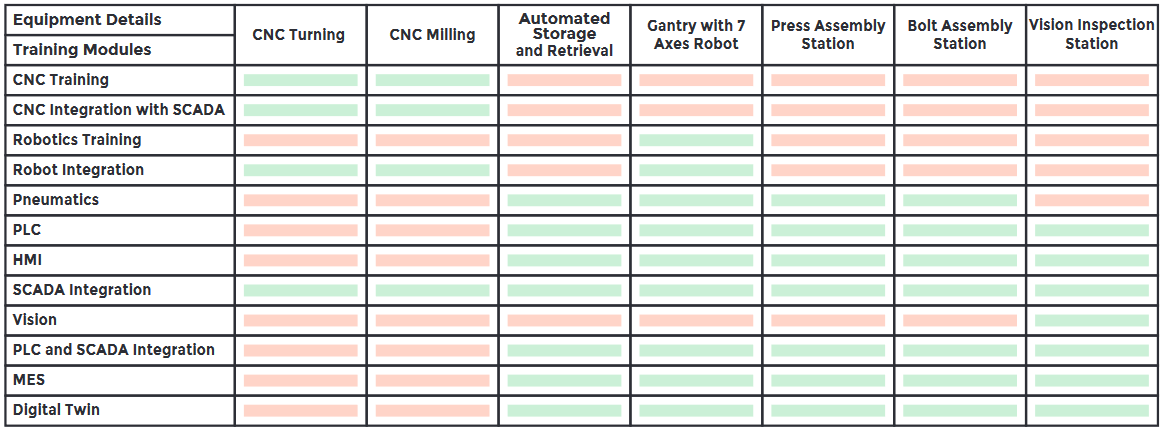

Various Training Modules in Computer Integrated Manufac- turing System:

- CNC Training

- Robotics Training

- PLC and HMI Training (Industrial Automation and Mechatronics)

- Smart Vision Training Module (Industrial Automa- tion and Mechatronics)

- Process Simulation with Digital Twin Integration

- SCADA Training Module

- MES Training and Integration

- IIOT Module

- Augmented Reality Training Module