SCARA Training Cell

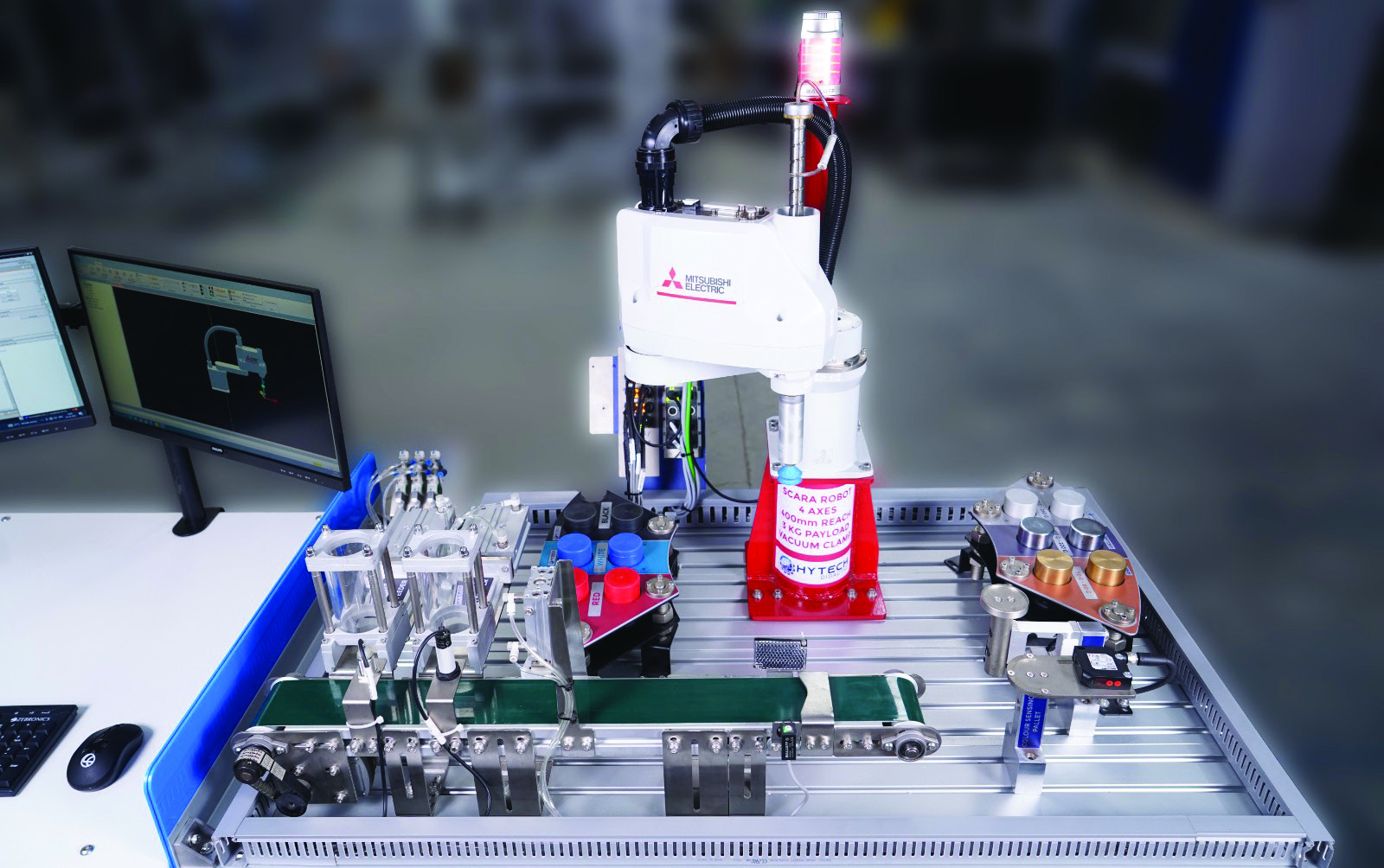

SCARA Cell integrated with PLC and IIOT HMI provides hands on experience on industrial SCARA applications. Color sensor with IO link connectivity and Load cell with amplifier are provided for sorting and palletizing application in integration with SCARA – PLC and IIOT HMI.

Provision of diffused photo sensors and shock absorbers for each sorting pallet in a SCARA cell provide necessary industrial automation experience to students.

SCARA cell is also equipped with a workstation and 3D simulation software which can act as a digital twin. Conveyor with a speed control mechanism is equipped with two separate auto feeder systems. User can utilize pneumatically actuated auto feeders for colour based and load based sorting applications. User can also utilize conveyors for palletizing applications.

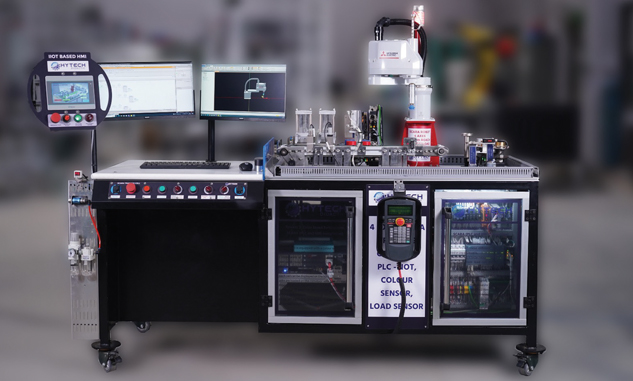

Structure

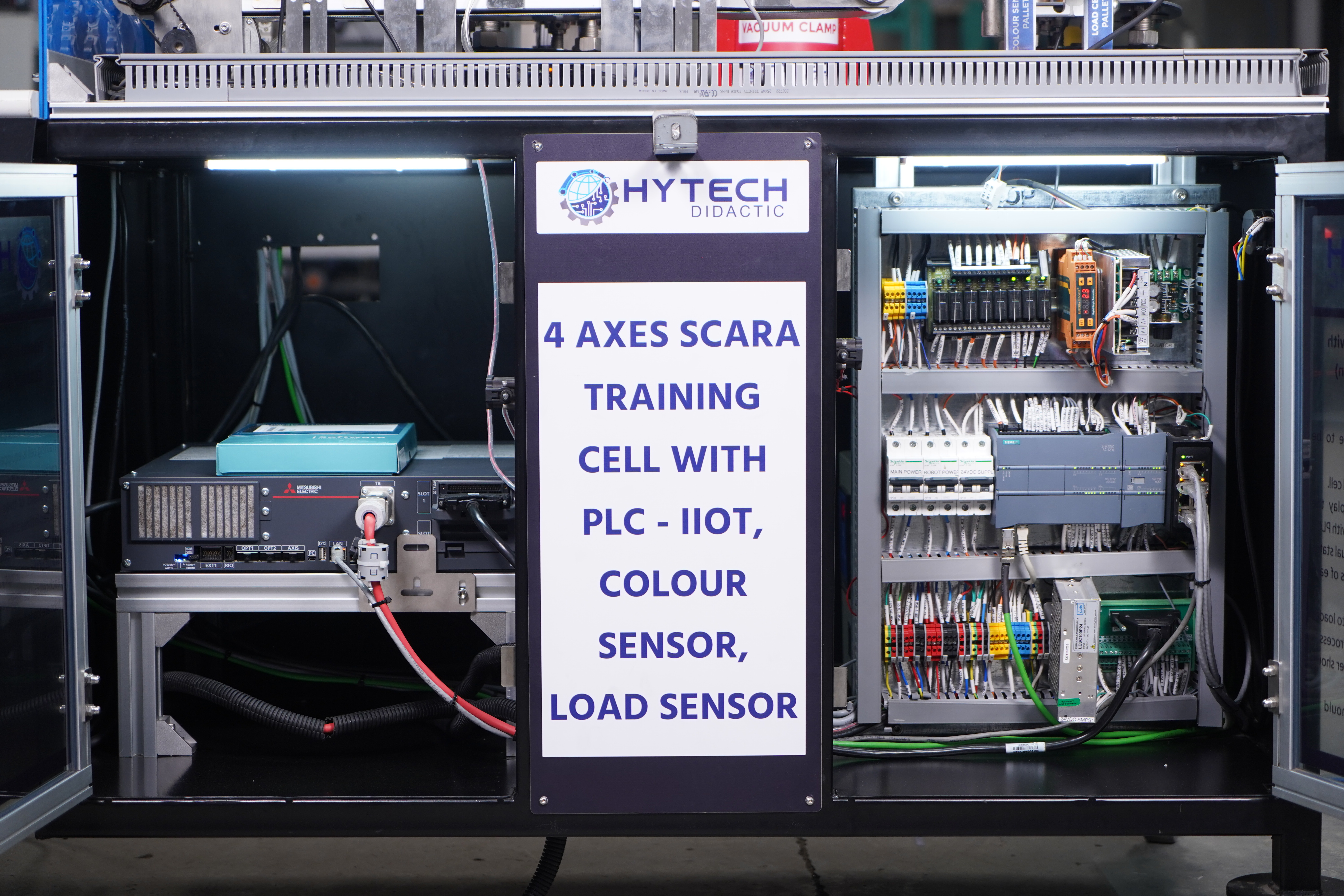

SCARA Training cell from Hytech Didactic is a mobile training station mounted on a Mild steel frame. Work surface for SCARA operation is made in aluminum extrusions. Control panel with PLC is mounted on the same structure along with dual monitors and IIOT HMI. Hardware operation panel is mounted on the training cell which can be utilized for automated operations of a cell.

Communication And Infrastructure

Smart Light, color sensor and photo sensors are integrated with PLC through i-o link communication. SCARA to PLC to HMI commination is Ethernet or profinet.

SCARA – PLC and HMI

SCARA Robot with 4 KG payload, minimum reach of 400mm and vacuum based end effector is provided in the training cell. Siemens or Mitsubishi PLC in complete integration with SCARA controller and remote operated HMI controls the cell operations. IIOT connectivity allows the user to operate the entire cell remotely from anywhere in the world.

Conveyor And Auto Feeder

Conveyor with two separate auto feeder stations is provided along with SCARA training cell which can be utilized for palletizing as well as automated training applications.

Process 1: Weight Based Sorting With Scara (PLC And HMI Integration)

Stacking in a stacker based on weight.

Components of three different types are to be stacked in separate cells.

Weight of the job is to be measured with load cell. Analog input from load cell should display the calibrated weight on the HMI in integration with PLC.

Photosensors provided for each cell give actual status of the cell (Empty / Occupies) to PLC. Status of each cell can be displayed on the HMI.

Process 2: Color Based Sorting With Scara (PLC And HMI Integration)

Stacking in a stacker based on Color.

Training cell is equipped with a colour sensor which can sense three different colours.

Components of three different colours are to be stacked in three different types of cells.

Photosensors provided for each cell give actual status of the cell (Empty / Occu-pies) to PLC. Status of each cell can be displayed on the HMI.

Jobs are loaded on the conveyor with an auto loader. Program should be selected from the HMI (Process 1 / Process 2) and the corresponding auto loader should be activated.

Once all cells are occupied, buzzer should be activated to indicate the operator.