Electrohydraulic Training Kit With

PLC – HMI And Relay Control

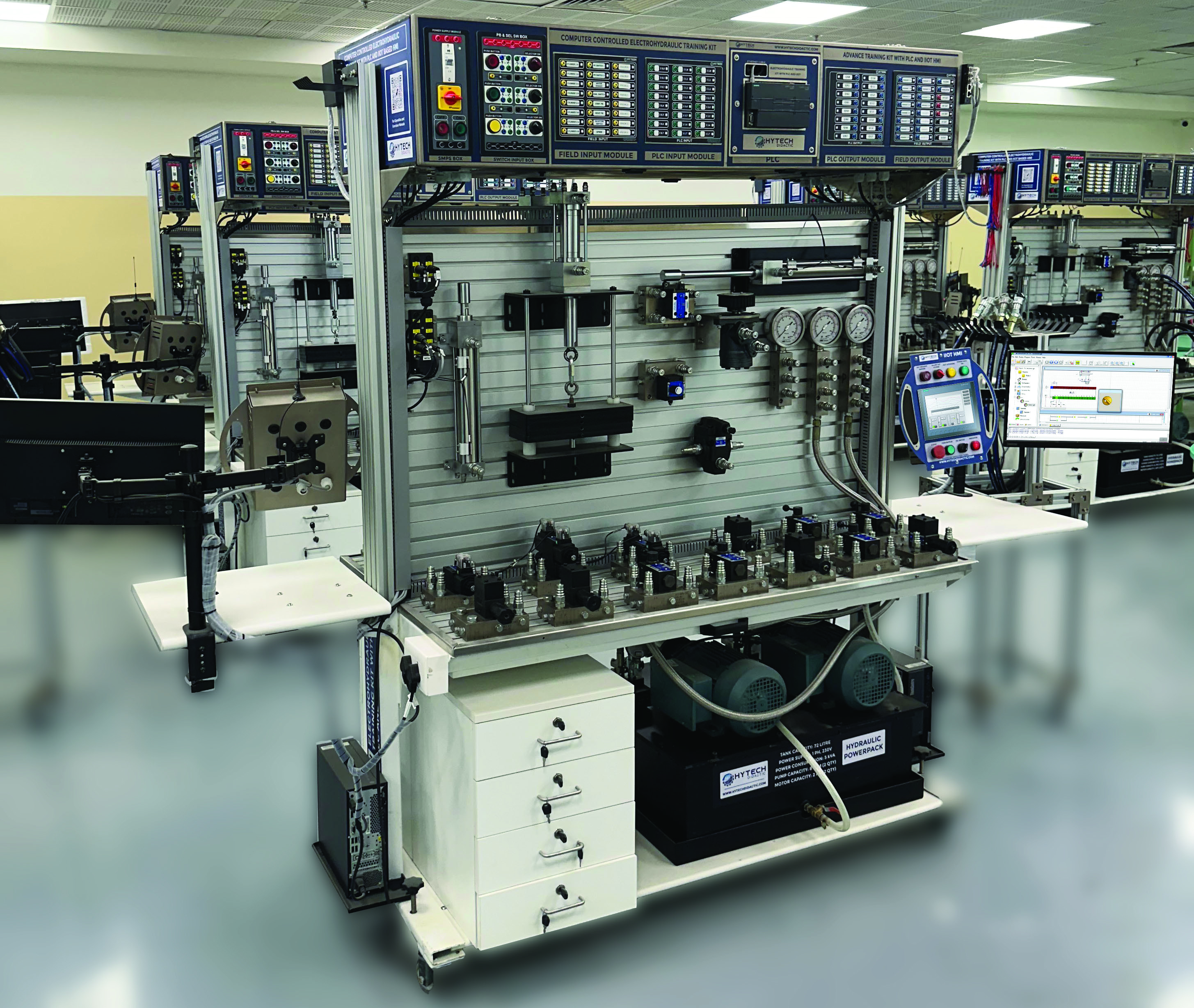

Hytech Didactic Electrohydraulic Training kit is mounted on a rigid Mild steel structure. The training kit is equipped with PLC, HMI as well as relay based operation modules. Control modules are made of industrial PCBs making the kit easy to operate as well as maintain.

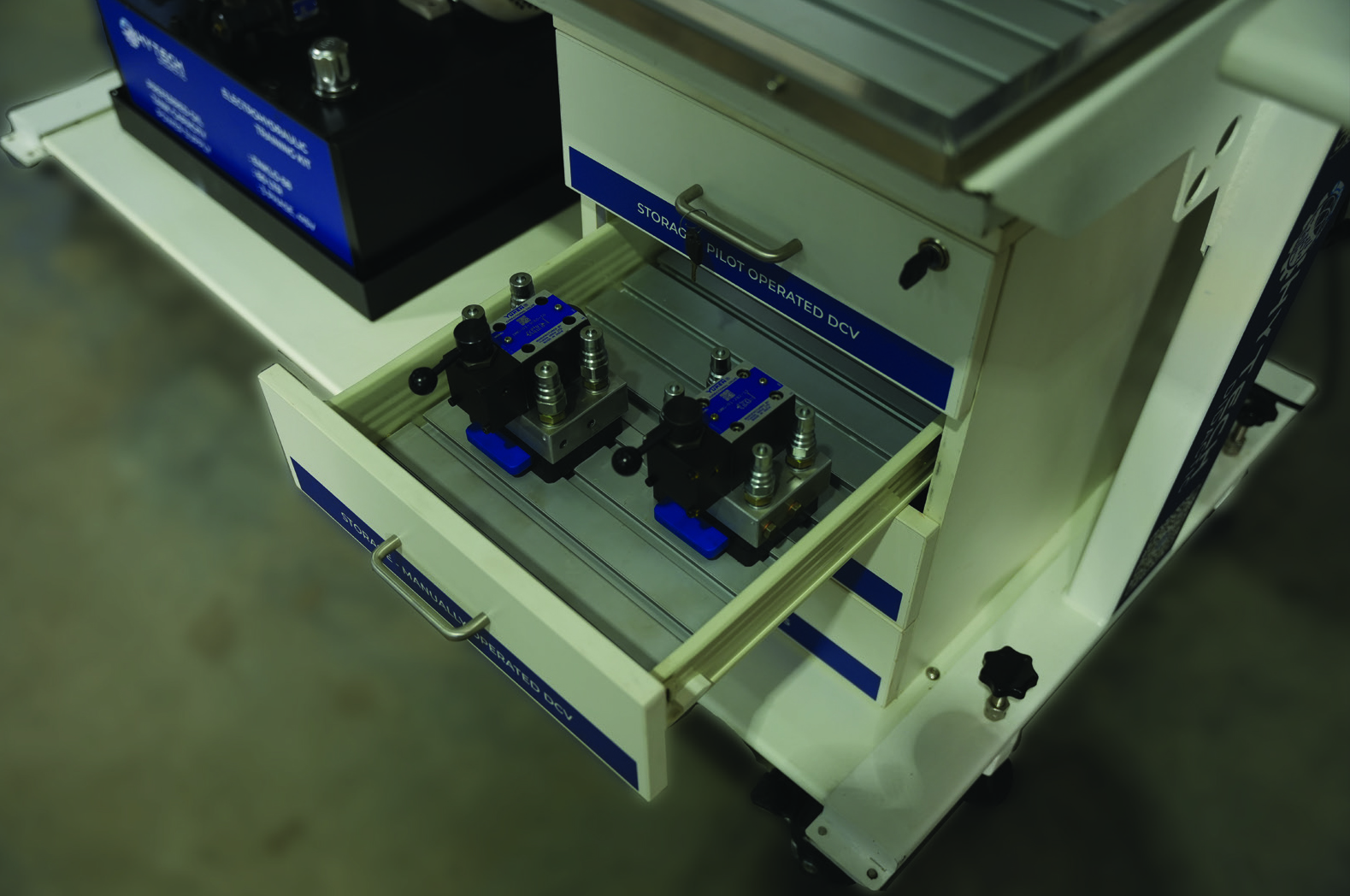

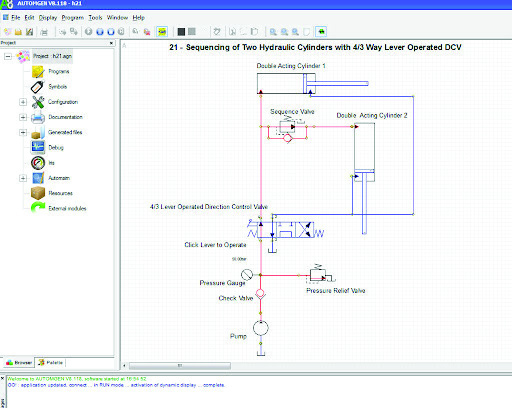

Electrohydraulic training kit comes with a dual faced worksurface made up of aluminium extrusions. Quick fix mechanisms for all valves makes it easier for users to engage and disengage the valves from Training kit. Quick fix mechanism makes it easy for users to store valves in drawers provided along with training kit. Solenoid valves as well as Cylinders are provided with PCBs for electrical connections. Industrial Valve plates for CETOP 3 mounting are tested at a pressure of 110 Bar. Each valve plate is marked with P, T, A and B ports and is equipped with Quick release couplings of 1/8 inch

Hydraulic power pack with a tank capacity of 60 Liter is tested for 120 Bar. Pressure and Tank manifolds are provided on both sides of the training kit with Quick Release Coupling.

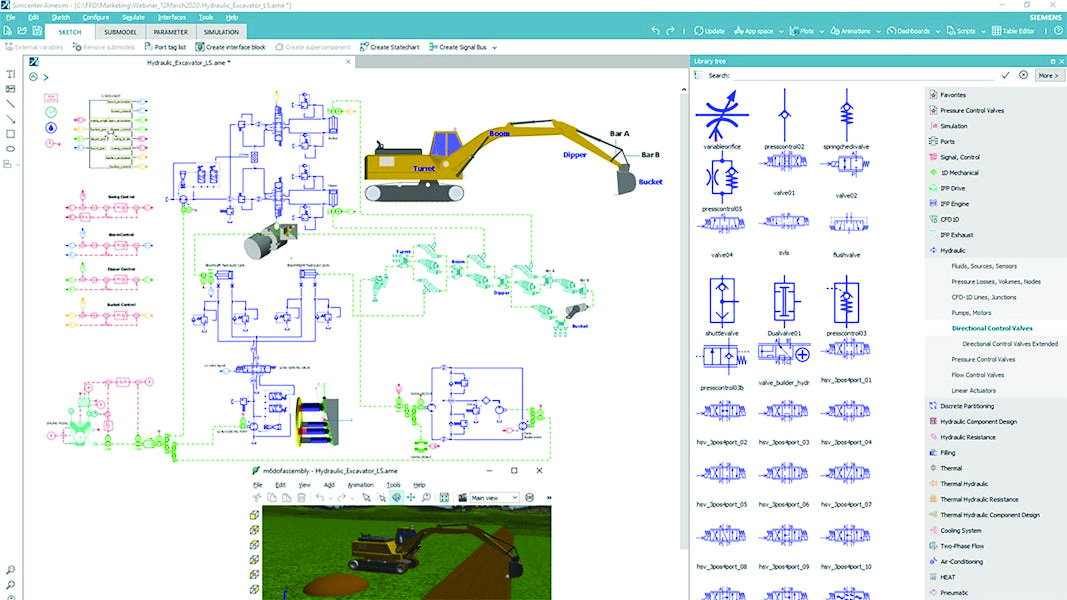

Control module is mounted at the top of a training kit. User can have a control module of PLC and Relays on both sides of the training kit which makes it truly a double sided training kit. Electrohydraulic Training kit can be seamlessly integrated with industrial automation modules such as Hydraulic excavator and Hydraulic Press.

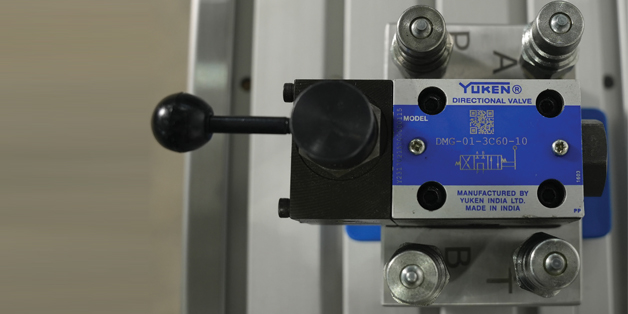

Quick Fixing Plates:

Hytech Didactic Electrohydraulic training kit

is equipped with indigenously developed

quick fixing plates which can be mounted

on the work surface without any external

tools. PCB for electrical connection is also

mounted on the plate.

Quick fix mechanism

makes it easy for users to store valves in

drawers provided along with training kit.

Solenoid valves as well as Cylinders are

provided with PCBs for electrical

connections. Industrial Valve plates for

CETOP 3 mounting are tested at a pressure

of 110 Bar.

Each valve plate is marked with P,

T, A and B ports and is equipped with Quick

release couplings of 1/8 inch.

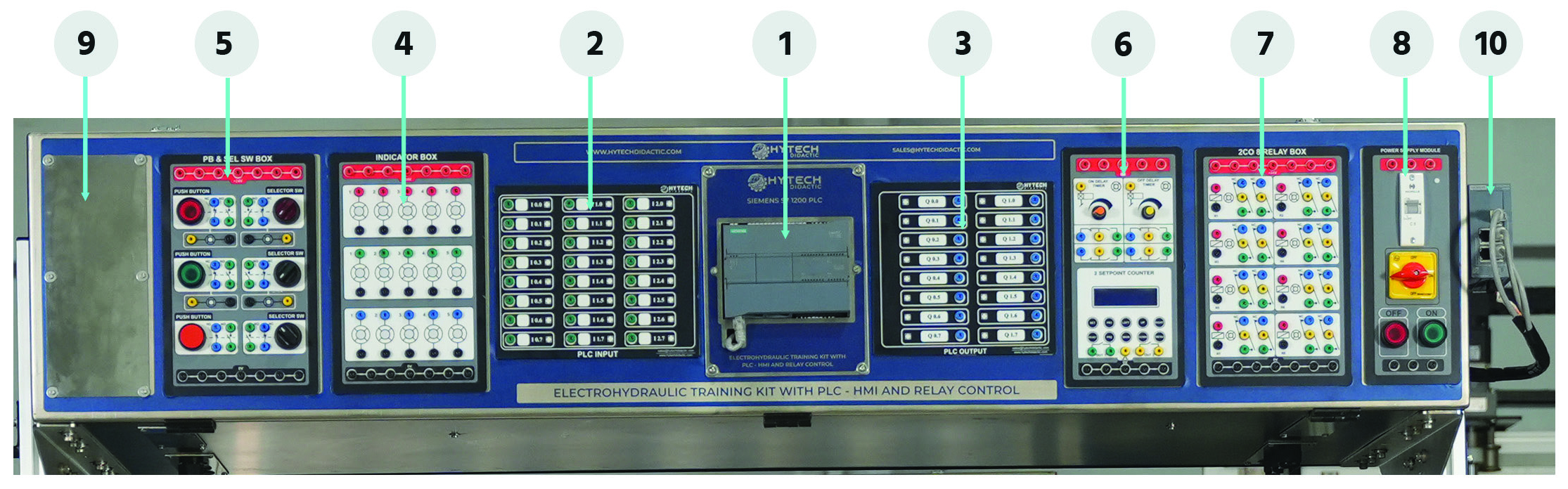

Control Box:

| 1. PLC (Siemens / Schneider) | 6. Electronic Timer and Counter Module |

| 2. PLC Input Module with 24 inputs and override buttons (With Indicators) | 7. 2 Change Over 8 Relay Module |

| 3. PLC Output Module with 16 inputs (With Indicators) | 8. Main Supply and Powerbank Module |

| 4. Indicator Box | 9. Spare |

| 9. Push Button and Selector Switch Module | 10. Unmanaged Switch for Workstation, PLC and HMI Communication |

Hytech Didactic Electrohydraulic Training kit is equipped with PLC – HMI control modules as well as relay based control modules providing hands on experience on both control logics for Electrohydraulic operations.

Each module of the control box except PLC input and output modules are provided with 24V power bank. User needs to connect the link of 2mm patch cord from Power ON module to activate this power bank.

PLC (Siemens S7 1200) and HMI (Siemens KTP 700) Module:

PLC module consists of Siemens S7 1200 PLC, Siemens KTP 700 HMI, TIA Software along with PLC Input and Output modules. PLC inputs are connected to PLC input module by hard wired connections. User can connect PLC inputs from this module with field inputs with the help of 2mm Banana connections. Each input on the PLC input module is equipped with a press button to override the input. . PLC outputs are connected to PLC output module by hard wired connections. User can connect PLC outputs from this module with field outputs with the help of 2mm Banana connections. User can program the experiments from PLC and HMI by designing the logic in Siemens TIA portal or directly from simulation software through OPC – UA.

Power Bank and Power ON Module:

User can switch On the compressor as well as entire kit from this module. This kit is also provided with 24V powerbank which is powered on along with the training kit. User needs to connect other modules with this power bank to switch them ON.

2 Change Over 8 Relay Module:

This module is equipped with 8 Qty 2 changeover relays which can be utilized to carry out relay control based Electrohydraulic experiments.

Electronic Timer and Counter Module:

For Relay control based Electrohydraulic operations, user can utilize this module for timer and counter based applications.

Indicator Module:

This module is equipped with 15 Qty indicators which can be utilized for relay control based Electrohydraulic applications.

Push Button and Selector Switch Module:

This module is equipped with various push buttons and selector switches which act as input sources for relay control based Electrohydraulic applications.